Our laboratory performs chemical-physical, thermal, rheological and mechanical analyses on polymer materials, composites and recycled materials.

We provide comprehensive characterization services for R&D, quality control and validation of materials and processes, with prototyping from 250 g to several tens of kilograms and data compliant with international standards.

MATERIAL ANALYSIS AND CHARACTERIZATION

Qualitative and quantitative characterization of materials, including complex blends and composites.

Thermal analysis

Assessment of thermal stability, melt behavior and material transitions.

Thermogravimetric Analysis (TGA)

Thermal stability, filler content, inorganic residues and volatile fraction.

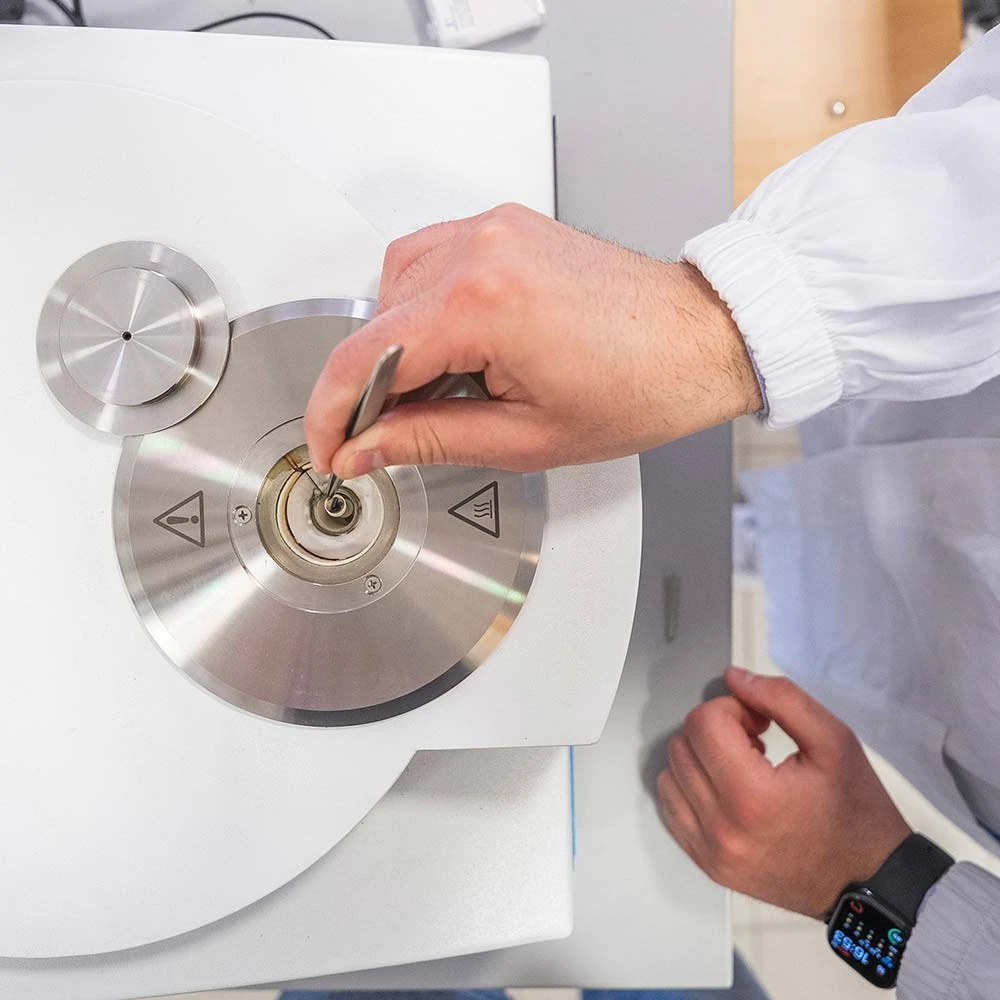

Differential Scanning Calorimetry (DSC)

Crystallinity, Tg, Tm, melt-state behavior and evaluation of heterogeneous blends or recycled materials.

Chemical, molecular and spectroscopic analyses

Identification of molecular structure, functional groups and polymer–additive interactions.

IR Spectroscopy (FTIR-ATR) and Raman Spectroscopy

Functional identification, compatibility assessment and degradation monitoring.

UV–Vis Spectroscopy

Optical absorption, photochemical stability and colorant analysis.

Selective solvent extraction

Compositional selectivity, additive analysis and purity assessment.

Melt flow and processability

Key analyses to understand viscosity, material stability and extrusion behavior.

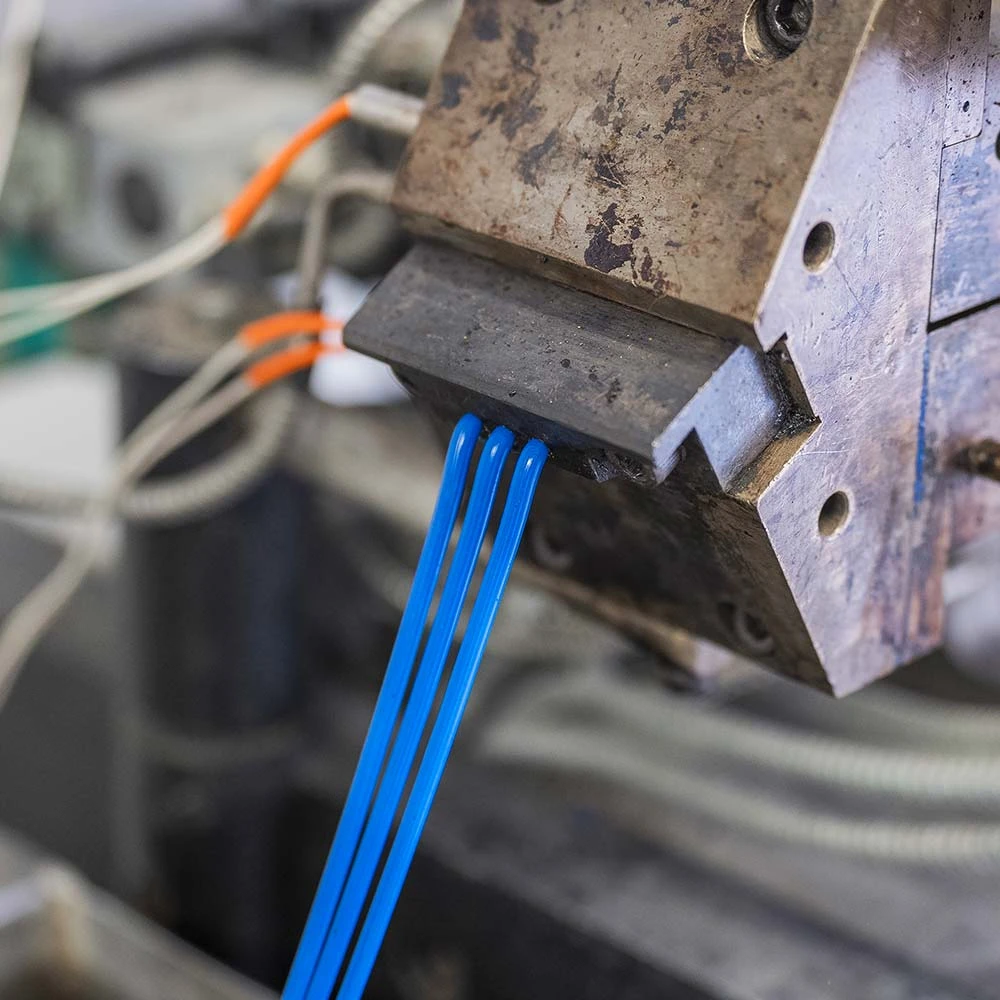

Pilot-scale co-rotating twin-screw extruder (Prism)

Advanced compounding, reactive extrusion, micro-batches and pre-scale-up

(250 g → 50–100 kg).

Lab-scale single-screw extruder (Brabender)

Preliminary evaluation of processability and controlled mixing.

Batch mixer (Brabender)

Formulation screening and preliminary assessment of blends and additives.

Melt Flow Index (MFI) analysis

Melt flow behavior, process stability and degradation control.

Certified test validated through the European RVEP circuit (Excellent Performance), ensuring high data reliability and reproducibility.

Standard specimen preparation and mechanical testing

SPINPET evaluates the mechanical properties of thermoplastics, thermosets and composites, both according to international standards and on experimental, non-standard formulations.

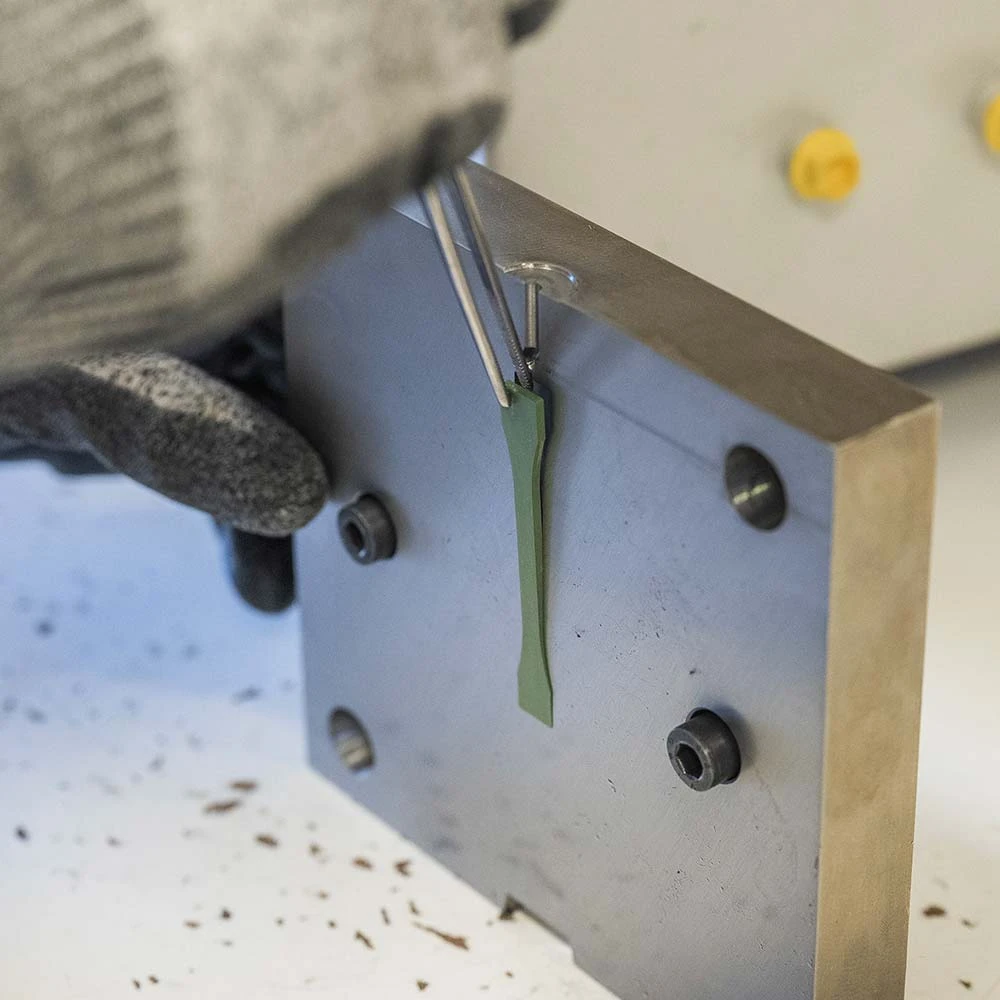

Specimen preparation using injection molding and compression molding presses

Injection molding and compression molding according to ISO/ASTM geometries, ensuring high repeatability even on complex or recycled materials.

Izod impact test (ISO 180 / ASTM D256) – notched and unnotched

Hot Set Test (IEC 60811-507) – permanent deformation at elevated temperature

Shore hardness A/D (ISO 868) – indentation resistance

Tear test (ISO 34, methods A and B) – tear resistance

Tensile test (ISO 527) – modulus, tensile strength, elongation at break

Flexural test (ISO 178) – flexural modulus (3-point bending)

Note

SPINPET laboratories perform the main analyses required by UNI 10667 for the characterization of recycled polymer materials.

This enables a comprehensive evaluation of recycled material quality and its suitability for the technical and performance requirements necessary for market placement under end-of-waste procedures.

Fire resistance testing

Flame behavior classification.

UL 94 flammability testing

Evaluation of flame response for polymer materials and composites.

Additional physical and mechanical analyses

Complementary tests for material, surface and process quality characterization.

Viscosity determination

Rheological evaluation under controlled conditions.

Density determination

Polymer classification and recycled material quality control.

Gloss measurement (surface gloss)

Aesthetic evaluation and surface finish assessment.

Do you need reliable data to validate a polymer material or a process?

SPINPET is a technical partner supporting you from test definition to result interpretation, enabling informed technical decisions.