At a time when environmental sustainability was not yet central to the public debate, we took a complex, seemingly unrecyclable bilayer and transformed it into a homogeneous, impact-resistant compound, ready for industrial processing.

This was achieved through reactive compatibilizers, molecular regrading and a strong problem-solving approach.

Impact-Resistant PET–PE Recycled Compound

SPINPET’s first project and the origin of our name

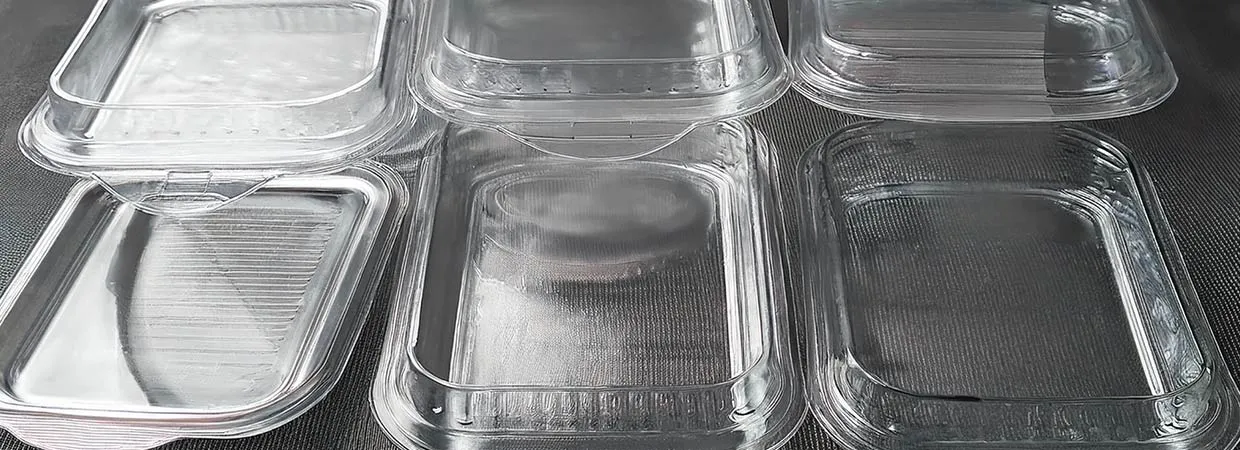

PET–PE multilayer recycling compound developed by SPINPET – Valorization of post-consumer bilayer packaging commonly used for food trays.

How we transformed a complex waste stream into a functional material: a concrete case of advanced recycling, targeted upcycling and applied innovation.

From formulation to market

Post-consumer bilayer packaging — especially PET/PE-based structures commonly used for food trays — represents a material that is extremely difficult to recycle and often considered waste with no future.

SPINPET transformed this complex waste into a functional, patented material, processable at industrial scale for applications such as thermoformable cladding for vertical surfaces in commercial environments, particularly within the retail sector.

The problem:

PET/PE/EVA, a challenging combination.

Post-consumer (and post-industrial) plastics often contain multilayer films, where:

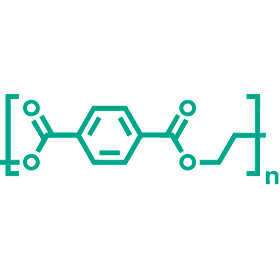

PET

provides mechanical strength and gas barrier properties

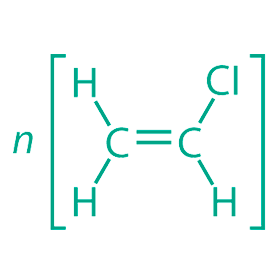

PE

ensures flexibility and sealability

EVA

s frequently present as a tie layer or adhesive

These polymers are chemically incompatible. In addition, the presence of adhesives complicates every recycling step, resulting in materials that are non-homogeneous, unstable and mechanically weak.

The technical challenge:

compatibilization and molecular regrading.

To address these issues and obtain an Impact-Resistant PET–PE Recycled Compound, SPINPET developed a twofold technical strategy:

- Compatibilization of immiscible polymer phases.

- Molecular regrading of PET to recover properties lost along the recycling chain.

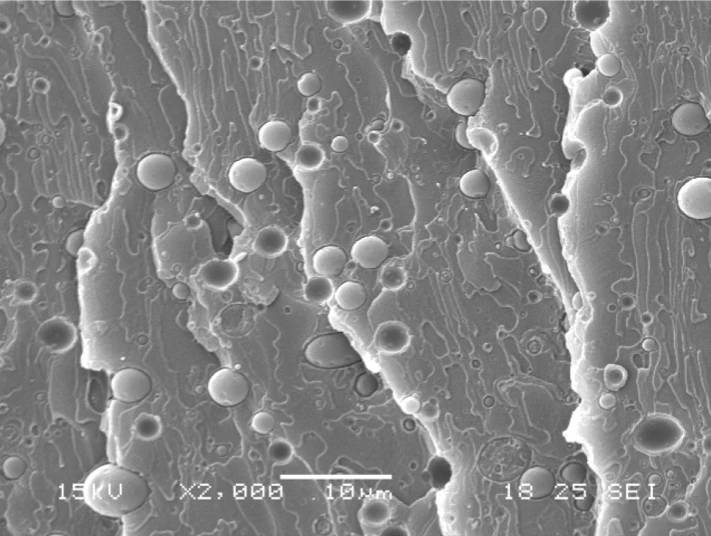

SEM of a Non-compatibilized PET-PE

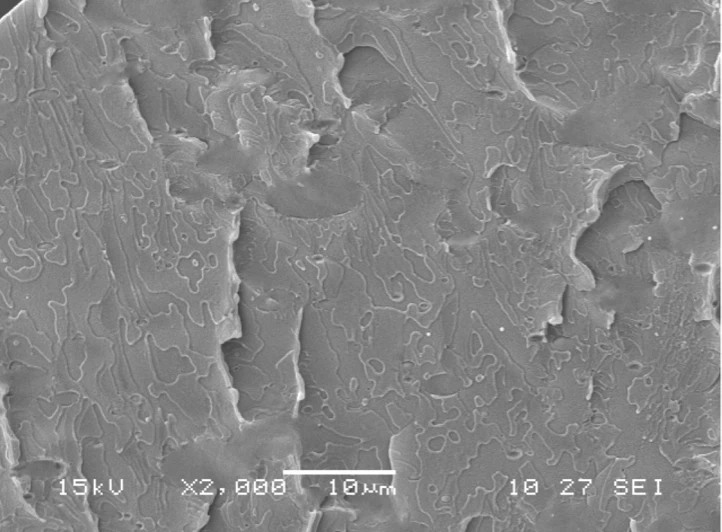

SEM of a Compatibilized PET-PE

The results:

a patented, processable, impact-resistant material.

The final formulation resulted in a flat-die extrudable compound featuring:

- excellent morphological homogeneity;

- impact-resistant properties;

- full processability on standard industrial equipment.

The technology is protected by patent ITPI20110090A1 (“Impact-resistant thermoplastic material based on polycondensation polymers and its production method”).

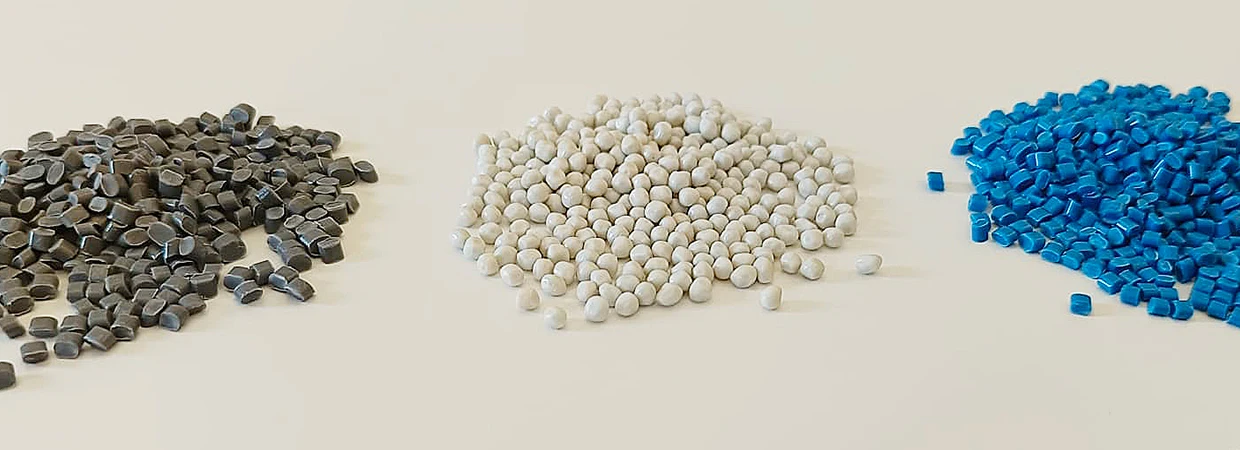

The resulting Impact-Resistant PET–PE Recycled Compound can be customized in a wide range of colors, making it suitable not only from a technical standpoint but also from an aesthetic perspective, for example in interior cladding of retail and commercial spaces, where visual performance is a key differentiating factor.

From formulation to market:

industrial network and customization.

Our work does not stop at the laboratory stage.

SPINPET works closely with compound manufacturers, providing the patented formulation and process guidelines needed to convert post-consumer material into high-performance pellets ready for final applications.

What does this project demonstrate?

- That even the most complex waste streams can be valorized through technical intelligence and industrial vision.

- That applied research can generate concrete, sustainable and scalable solutions.

- That SPINPET is the right partner for companies aiming to innovate materials starting from what is currently considered waste.