SPINPET designs and develops polymer and (nano)composite materials through tailor-made formulations, advanced compounding and multi-scale prototyping, in order to verify real performance, stability and processability — even in complex applications and when dealing with heterogeneous recycled materials.

FORMULATION AND PROTOTYPING

From molecule to pellet: developing materials ready for industry

Advanced formulation of polymer materials

At SPINPET, formulation activities always start from a rigorous analysis of application requirements: required mechanical performance, processing constraints, regulatory compliance and sustainability targets.

In most projects, we go beyond simple blending. We act directly on material chemistry through advanced transformation techniques — in particular reactive extrusion — to obtain more stable, compatible or functional structures. Activities include:

- design of new compositions (blends, copolymers, bio-based and recycled materials);

- compatibilization and interface engineering for complex systems (PET/PE, recycled polyolefins, textile or leather residues);

- controlled grafting and introduction of functional groups;

- chain extension and branching to restore viscosity or improve mechanical strength;

- controlled crosslinking and thermal stabilization;

- surface functionalization and modification of interfacial adhesion.

This approach is particularly effective when working with recycled materials or heterogeneous waste streams, where compatibilization is often the key to achieving reliable performance.

It also allows fine-tuning of properties such as elasticity, stiffness, impact response, thermal stability, barrier performance and aesthetic quality, up to the development of proprietary materials or advanced compounds.

Typical applications include impact-modified materials, injection molding compounds, upcycling solutions for complex waste streams, bio-based formulations free of restricted substances, and technical composites for packaging, automotive, furniture, fashion and industrial products.

The final outcome is a technically robust, predictable and reproducible formulation, ready to be transferred to compounding and scale-up phases.

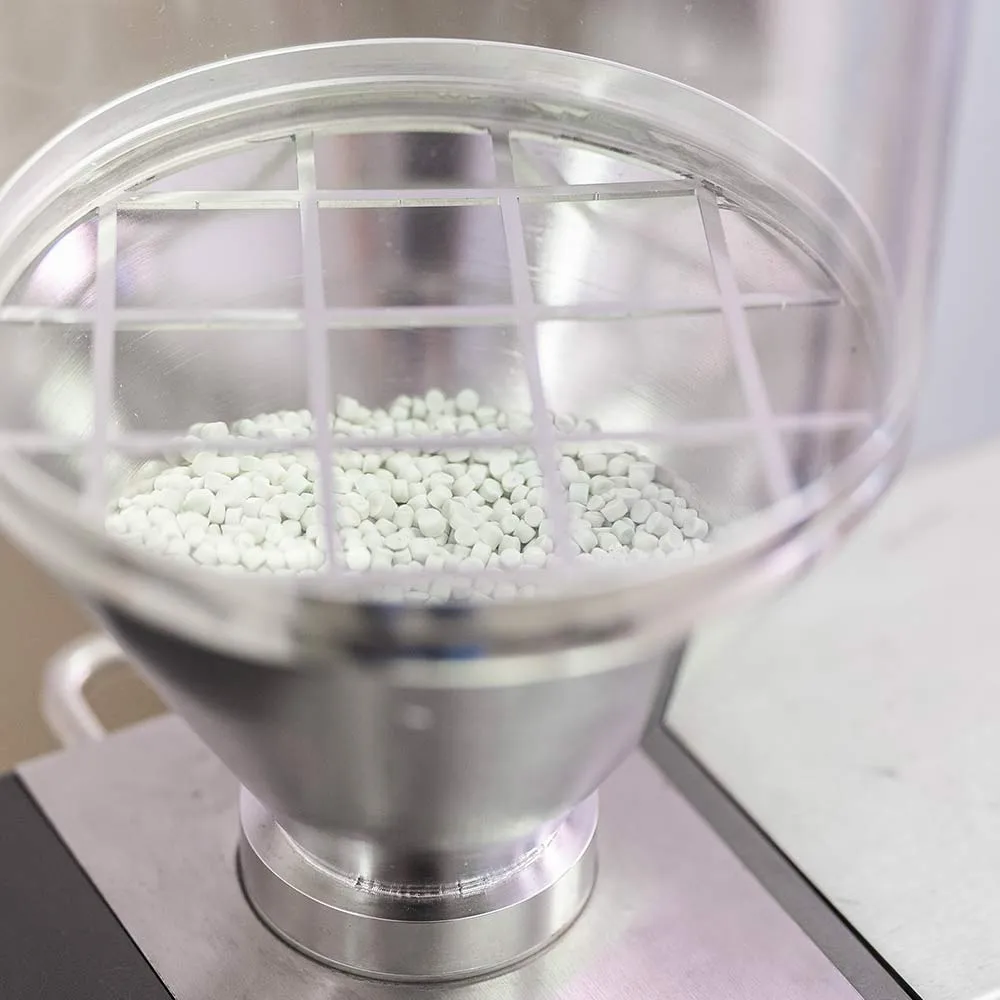

Compounding and pilot-scale development

SPINPET’s laboratory is equipped to manage complex compounding, reactive blends and heterogeneous recycled materials, thanks to single-screw and co-rotating twin-screw extruders that allow reproduction of industrial processing conditions.

This enables precise control of mixing, assessment of thermal stability, verification of filler dispersion and production of pellets already suitable for molding or further processing.

A distinctive feature of our laboratory is the ability to operate at multiple production scales: we produce prototypes from 25–250 grams for preliminary screening, 2–5 kg batches for full mechanical and rheological testing, and productions up to 50–100 kg for trials on industrial equipment or pre-series runs.

This polymer formulation and prototyping approach allows verification of processability not only in the laboratory but also directly on customer production lines, significantly reducing the risk of non-conformities before industrial scale-up.

Prototyping and performance validation

A formulation is not complete until it has been validated under real operating conditions. For this reason, SPINPET performs analytical testing and material characterization on standardized specimens and functional prototypes, in order to fully validate the material, identify potential critical issues and precisely define the parameters required for scale-up or industrial production.

SPINPET’s formulation and prototyping activities are particularly effective when a company needs to:

- replace materials with more sustainable alternatives without compromising performance;

- create recycled compounds with targeted properties;

- overcome processability or stability issues;

- develop proprietary or patentable materials;

- test scalability prior to industrial investment;

- demonstrate technical feasibility in funded projects or value-chain collaborations.

From impact-resistant materials developed from bilayer waste, to pellets obtained from post-consumer textiles, to bio-based formulations free of restricted substances: each project demonstrates how materials science, applied chemistry and industrial processes can converge into a concrete, industrial-ready result.

Do you need to develop a new material or validate the scalability of a formulation?

SPINPET supports you from chemistry to pellet, up to the functional prototype.